We recognize that research and development is vital to our success and our primary focus is to meet our customers’ evolving needs. We also strive to improve the quality and yield of our existing products while at the same time reducing the cost of production.

We continuously conduct research to improve our processing in terms of materials, heat treatment, precision processing and high accuracy measurement for use in high speed, high load, and high temperature conditions, for applications requiring weight and size restrictions.

We conduct our research and development efforts throughout our facilities globally. Our production line is constantly assessing ways to improve production efficiency and the quality of our products through multi-discipline task force teams.

Meeting sophisticated customer needs

The demand for noise reduction is ever increasing due to the expectations for higher performance in our automobiles and our everyday products.

For low-noise bearing applications it is essential to reduce the noise levels of the component parts. This drives an increasing demand for precision balls and rollers with superior noise reduction capabilities.

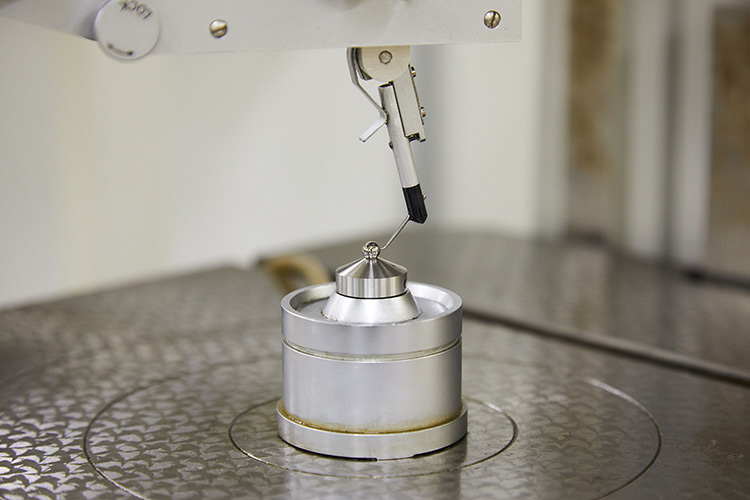

For high-speed bearing applications, minimizing the vibration requires the use of high precision balls and rollers to achieve the low vibration performance needs.

We have a long history of producing the highest precision balls and rollers by accumulating our many years of R & D and production expertise to offer our customers the best choice for their low noise and low vibration needs.

Production quality improvements and cost efficiency

Here at Tsubaki Nakashima we are continually working to improve our manufacturing process to deliver improved quality and cost efficiency to our customers.

Our initiatives include the improvement of the pressing operation, which is the first step in our manufacturing process, as well as automation and digitization of process control information.

Through our efforts we will achieve a reduction in raw material and consumables waste, reduce processing time, and extend tool life.

Accumulated experience and know-how in precision ball screw production over many years

We have manufactured precision ball screws beginning in 1959 to the present. We have been supporting customers with high quality products responding to the increasingly sophisticated needs of our customers to contribute to their competitiveness in the future.

By applying our accumulated technology, we have developed the FB Series with a C3 class accuracy for precision rolling ball screws, which is an advancement from the previous limit of C7. We have developed the world's first precision ball screw using a retainer for high loads. In addition, we have gained the trust of many customers for the overwhelming results of our large ball screw manufacturing facilities.