blowers

Decades of Industry Leadership

Our Group has been engaged in the development of wind-generation technologies for nearly 100 years*, growing in step with the advancement of Japan’s modern industries. By leveraging decades of accumulated technology and know-how, we provide optimal fan and blower solutions tailored to customer needs. As a leading manufacturer in the industry, we are highly regarded not only in Japan but also overseas, serving a broad range of industries including thermal power, nuclear power, and steel.

*In 1996, our company was integrated through a business combination with Nakajima Manufacturing Co., Ltd.

Custom Made

We deliver over 16,000 custom-made products to meet unique industrial requirements.

High Efficiency

Achieving the highest efficiency in the industry, our blowers deliver maximum performance with minimal energy loss.

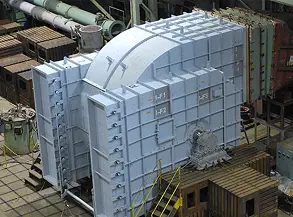

Large & Special Products

We design and manufacture a wide range of industrial fans and blowers, including large-scale units with motor capacities exceeding 4,000 kW, systems for high-temperature and special gas environments above 700°C, as well as models engineered for severe wear- and corrosion-resistant applications.

primary markets

Iron & Steel

High temperatures and high pressures in the iron and steel industry require stable operations despite harsh conditions. We provide safe and reliable products that are resistant to wear and corrosion, high temperature and special gases (e.g. COG, LDG, BFG). We also provide post-delivery support to meet individual customer needs.

Delivery Track Record: JFE Steel Corporation and numerous leading domestic blast furnace and electric arc furnace steel manufacturers

Applications: IDFs for OG systems, COG boosters, steam exhaust fans, dust collection fans, direct-fired fans, hydrochloric acid recovery fans, nitrogen (N₂) purge fans, preheating fans, BUFs, coal discharge equipment, and related systems

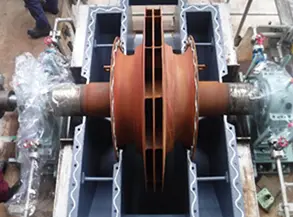

Dust collector fan

- Ceramics or hardened plates can be attached to impeller surfaces for use in an abrasive environment

- High efficiency turbo fan that matches the efficiency rating of an airfoil fan, ideal for eliminating costs

Induced Draft Fan for oxygen converter gas recovery system

- Excellent corrosion resistance

- Shaft seal provides excellent leak resistance

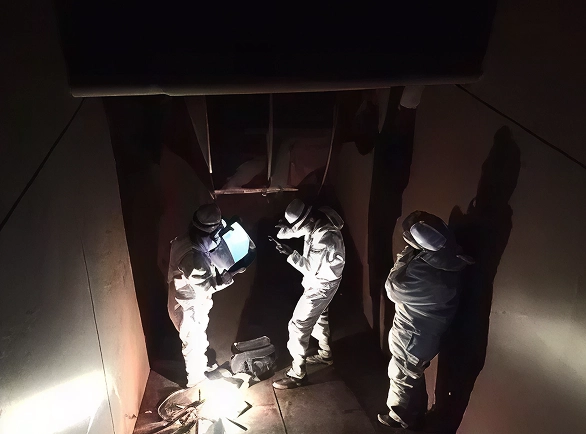

Maintenance

- We can perform expert field surveys to provide you with a customized maintenance plan

Electric Power

As global electricity generation continues to grow, the importance of stable and reliable power supply is increasing.

With a proven track record across nuclear and thermal power plants, our fans and blowers operate under stringent requirements, delivering stable operation, long service life, and excellent maintainability. We provide high-quality, custom-engineered solutions backed by decades of operational experience.

Delivery Track Record: JERA Co., Inc., along with numerous major domestic thermal power plants, nuclear power plants, and biomass power facilities

Applications:

– Thermal power: GRF, GMF, IDF, FDF, PAF, FECF, MSAF, Gracon fans, and related equipment

– Nuclear power: ventilation and HVAC fans, fans for safety-critical and designated important equipment

Forced Draft Fan (FDF)

- With vanes that mimic the shape of an airplane wing, this has proven to have the highest efficiency with minimal noise among all centrifugal blowers

- Inlet Guide Vane controls the flow rate and provides power savings

Induced Draft Fan (IDF)

- Hardened plate attachments for use in abrasive environments

- High efficiency turbo fan that matches the efficiency of an airfoil fan, reducing costs

Primary Air Fan (PAF)

- High efficiency turbo fan that matches the efficiency of an airfoil fan

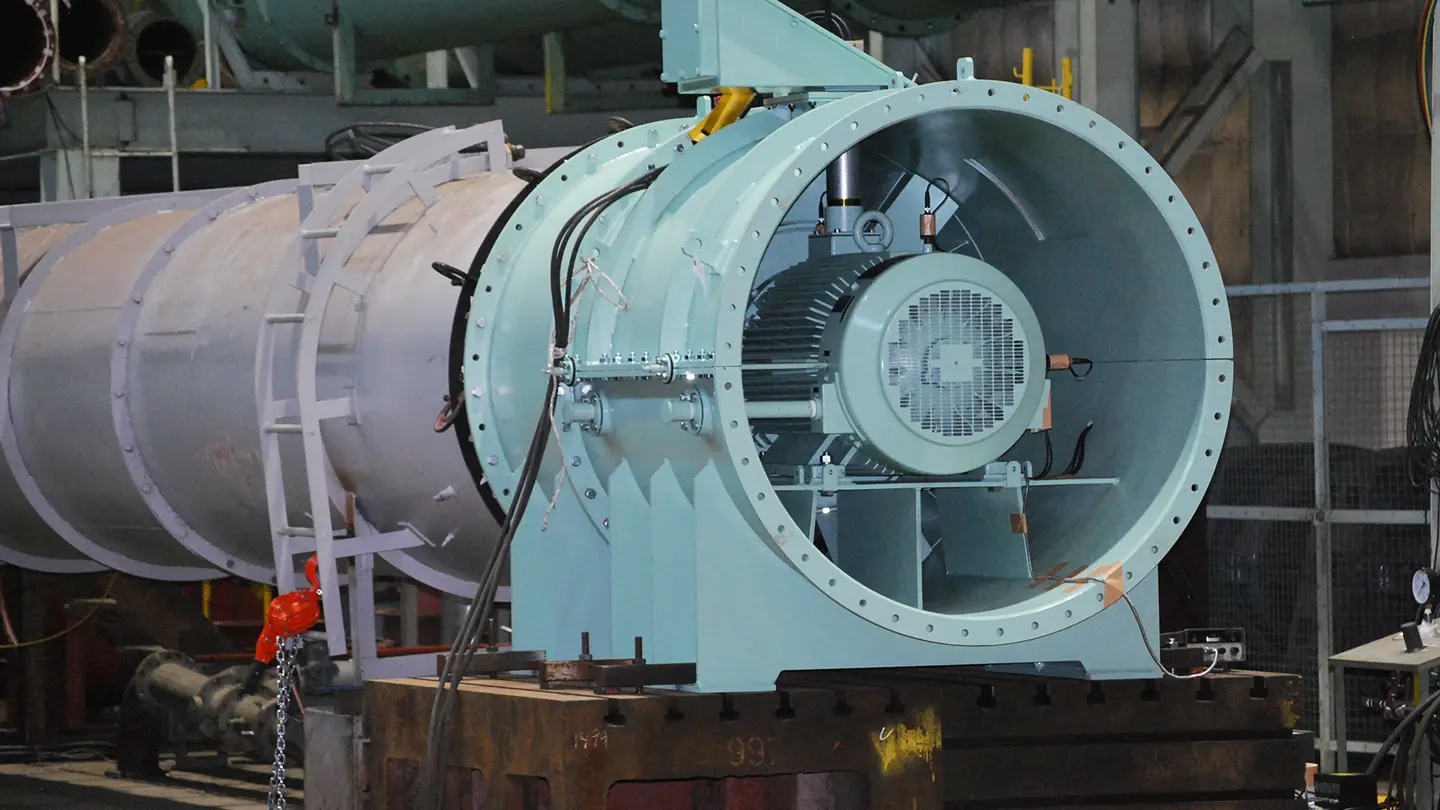

Wind Tunnel

Wind tunnel testing facilities artificially reproduce and observe real-world fluid flows, with fans playing a critical role in generating controlled airflow. Data obtained from these tests supports the continuous development of automobiles, motorcycles, sportswear, and other products.

Fans are also used in environmental testing models to evaluate wind effects caused by buildings, particularly high-rise structures, and their impact on surrounding areas. By delivering fans capable of generating highly accurate airflow, we support ongoing technological advancement.

Delivery Track Record: Numerous major domestic automobile manufacturers and research institutes

Axial Fan

Axial Fan

Other Fans and Blowers

Fans and blowers are used across a wide range of applications, including roads and subways requiring ventilation, manufacturing plants for steel and chemical materials that underpin Japan’s industrial base, as well as downstream processing facilities.

Amid diverse operational requirements, we provide more than high-quality products alone. Our fans and blowers are engineered with durability and safety in mind and are supported by comprehensive after-sales service. We remain committed to ensuring that our customers can rely on our equipment for long-term, stable operation.

Ventilation fan

- Proven to have the highest efficiency with minimal noise among all centrifugal blowers

Multi-stage impeller

- Multi-stage impeller is a centrifugal fan covering a wide range of blower applications including High Pressure Blower.