Launch of Microfluidic Plate Manufacturing Capabilities for the Engineered Plastics Components Business

Tsubaki Nakashima has launched manufacturing capabilities for microfluidic plates, enabling customers to expand their microfluidics-related businesses.

Through a strategic partner, our Engineered Plastic Components business has already established initial manufacturing capabilities in the UK. This includes equipment that supports customer collaboration on design and prototyping, enabling the development of application-specific solutions.

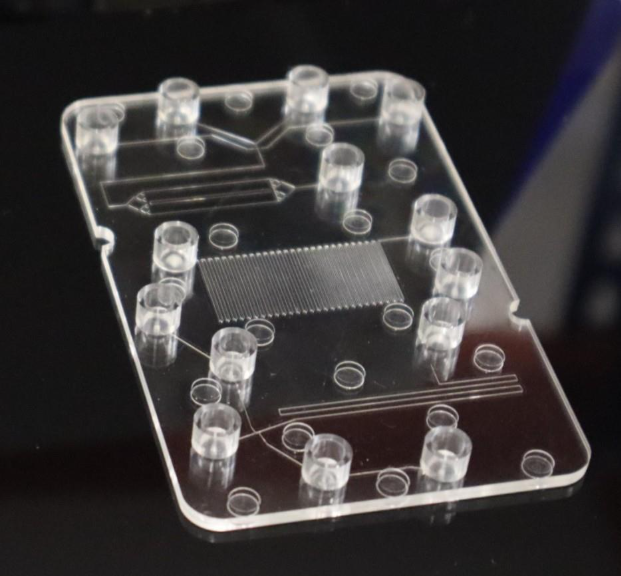

A microfluidic plate is a component within the microfluidic technology platform that enables the precise control and manipulation of extremely small volumes of fluids—often at the nanoliter or picoliter scale—within micro-scale channels. By integrating processes such as sample preparation, reaction, separation, and detection onto a device, microfluidic platforms can deliver faster results, reduce reagent consumption, and achieve higher analytical sensitivity compared with conventional laboratory methods.

The global microfluidics market is experiencing rapid growth, driven by several key trends. These include the evolution of diagnostics, such as point-of-care (POC) molecular testing; growth in biopharmaceuticals and cell therapy; expanding applications in next-generation sequencing (NGS) and genomics; and increasing demand for consumables in environmental, food, and industrial testing, as well as other emerging applications. In addition, the convergence of microfluidics with advanced technologies such as AI and IoT is expected to further accelerate market expansion.

Producing microfluidic plates requires advanced manufacturing capabilities, including tight-tolerance precision injection molding and complex assembly processes.

Tsubaki Nakashima manufactures engineered plastic components in Class 8 cleanrooms located in Sault Ste. Marie, Michigan, USA and Mirandola, Italy, enabling high-quality and scalable production to meet customer requirements.

By leveraging Tsubaki Nakashima’s global manufacturing network, we provide access to a wide range of plastic materials optimized for microfluidic performance, biocompatibility, and optical clarity. Tsubaki Nakashima also supports customers from the early stages of concept development through full-scale production, offering engineering collaboration and the flexibility to scale manufacturing capacity in line with customer demand.

With the launch of microfluidic plate capabilities, Tsubaki Nakashima is well positioned to support customers’ quality requirements and growth ambitions in the rapidly expanding microfluidics market.

Guided by its Purpose, “Help the world to move by the power of precision,” Tsubaki Nakashima will continue to support customers’ success by delivering high-quality products, driving innovation, and contributing to keeping the world in motion.

- Microfluidic Plate sample

For more information, please visit the related blog article .<Microfluidics CartridgeInjection Molding: The Next Frontier in Diagnostics & Life Sciences (2025–2030) >.

About Tsubaki Nakashima

Tsubaki Nakashima specializes in the manufacturing and sale of precision components for industrial applications. Utilizing materials such as ceramics, steels, and plastics, we produce more than 20,000 product types, including high-precision balls, rollers, large-scale blowers, and contract injection molding. For over 90 years, our expertise, experience, and global network serving the automotive, industrial, aerospace, and medical industries have built our reputation for excellence, innovation, and quality — while supporting people’s everyday lives.

Guided by our purpose — to help the world to move by the power of precision — we are committed to building a truly sustainable future, recognizing our responsibility to those who work with us and to the world around us.

Tsubaki Nakashima (securities code: 6464) is listed under prime market of Tokyo Stock Exchange. Learn more at https://www.tsubaki-nakashima.com/en/