Outstanding performance

Outstanding performance by experts in injection molding of medical components and precision beads.

We offer optimal solutions for the highest Quality and cost effective solutions in plastic component production.

About us:

Our company manufactures precision plastics beads and clean room injection molded components suited to meet the needs of our customers design. Thanks to one of the most established precision ball manufacturing and sales network in the industry. We can respond to various types of requests and work to find the best solution to meet our customer needs. This includes volume demand, competitive procurement and short lead times.

Why Tsubaki Nakashima is chosen in the industry:

Reason.01

A leading company for plastic beads, and contract injection molding. Capabilities include Class 8 Clean room molding, ISO 13485 registered and FDA Complaint.

Reason.02

With over 40 years of experience in the manufacture of precision plastic beads and injection molding. We manufacture with strict tolerances, scalable to customer needs and various manufacturing processes, we can guarantee the highest quality for the lowest costs.

Reason.03

We can offer a variety of raw material types to suit your application. Full lot traceability from raw material to finished product, and utilize a network of partnered resin manufacturers and distributors.

Do you have any challenges with your existing plastic bead or Injection Molding suppliers?

- 01. Are you not provided the most cost effective option?

- 02. The product needs require injection molding in a clean room?

- 03. There are challenges in consistently receiving high Quality products and services?

Extensive experience in plastic beads and plastic injection molding services. Our plastic injection molding services are a perfect match. We can efficiently and accurately manufacture plastic parts along with top level service to meet many application needs required throughout all industries.

01. Are you not provided the most cost effective option?

We will work with you to find the most cost effective options and materials to suit your needs.

Through our expertise and experience in the industry we can achieve great cost competitiveness through various optimization and efficiencies.

By our reduced overhead we can maintain long term cost competitiveness in our partnership.

02. The product needs require injection molding in a clean room?

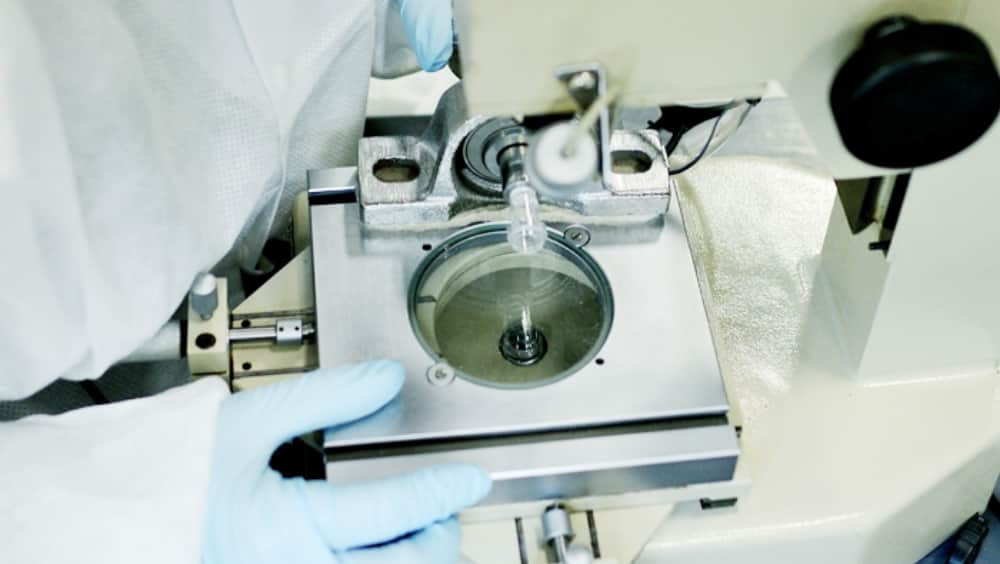

Establishing Your Production Line in a Cleanroom Environment

Class 8 and FDA compliant clean room certified to ISO 13485, with over 40 years experience in the industry.

03. There are challenges in consistently receiving high Quality products and services?

We are recognized by many of the top 10 medical OEM's worldwide for our continued top performance in Quality, Delivery and cost.

In addition through stringent quality assurance systems and processes, we are able to provide unmatched consistency and efficiency to maintain a zero defect Quality vision.

Case study

-

Customer A -

Customer A was in need of plastic beads that could be safely used and coated with the customers specific chemistry. By working with our customer to find the proper bead surface finish and treatments necessary the customer was able to find a perfect match for their application.

-

Customer B -

Customer B needed lightweight balls that could ensure appropriate mixing with their specific chemistry. Unlike metal and alloy balls, plastic beads made from properly matched resins, can ensure that customer chemistry applications can be achieved with lighter weight beads and without leaching, corrosion, or other contamination concerns often found in metals and alloys.

-

Customer C -

Customer C was looking for beads which could work best in terms of size and accuracy for their intended application. Through the wide variety of plastic materials and bead sizes, we are able to sample many variations to allow the customer to find the perfect match for their application.

FAQ

- Do you offer custom injection molding services for medical device components?

- Yes, we specialize in working with our customer to build the best custom molds and services to manufacture products in strict conformance to customer specifications.

- How do you manage the quality of medical components you manufacture?

- We have a robust Quality Assurance system with decades of medical industry experience. Through various incoming, in-process and final inspections and specialized testing methods. We can ensure every product and batch manufactured conforms to the highest levels of Quality.

- How is pricing for medical components set?

- It various depending on whether the customer is needing to have a mold constructed, or already has a mold and would like to have us manufacture from. Through our low overhead and geographical location and experience in the industry we are able to offer highly competitive pricing and delivery while continuing to provide medical industry leading Quality products.